In the world of fine jewelry, a quiet revolution is taking place that marries centuries-old craftsmanship with cutting-edge engineering. The concept of transformable jewelry—pieces that can be worn in multiple configurations—is not entirely new, but recent advancements in mechanical design have elevated this category from novelty to ne plus ultra. These are not mere trinkets with interchangeable parts; they are miniature marvels of engineering where a single piece of jewelry can morph into several distinct forms, each with its own character and wearability.

The foundational principle behind these ingenious creations is a deliberate and sophisticated application of mechanical joints, hinges, and locking mechanisms, all executed on a breathtakingly small scale. Unlike a watch movement, which is hidden from view, the mechanics of transformable jewelry are often part of the aesthetic appeal. Artisans and engineers collaborate to design systems that are both intuitive for the wearer to operate and robust enough to withstand daily use. The challenge is immense: to create moving parts that are precise, durable, and, crucially, beautiful.

One of the most common mechanisms is the strategic use of pivots and hinges. A necklace might feature a central pendant that can be detached and, with a few deft movements, its elements reconfigured into a pair of earrings and a ring. This is achieved through tiny, almost invisible hinges that allow components to swing into new positions, locking securely into place with an audible, satisfying click. The precision required for these components is microscopic. A hinge pin might be thinner than a human hair, yet it must bear the weight of precious metals and gemstones without failing.

Another engineering triumph is the development of modular locking systems. Think of it as a sophisticated, high-end version of building blocks. Individual segments of a bracelet, for instance, can be disconnected and reassembled in a different order to change its pattern, or combined with elements from other pieces to create an entirely new item. The locks are often magnetic or employ a subtle clasp mechanism that is seamless when engaged but easily released with a specific, knowing pressure from the wearer. This requires phenomenal tolerances in manufacturing; each connector must be perfectly machined to ensure a flush fit and secure hold in every possible configuration.

The role of material science cannot be overstated. The metals used must possess a unique combination of properties: they must be malleable enough to be shaped into intricate parts, yet possess tremendous tensile strength to avoid deformation. Precious metals like platinum and high-karat gold are favored for their durability and luster, but they are also soft. Engineers often alloy them with minute amounts of stronger metals or employ innovative hardening techniques to ensure the microscopic mechanisms withstand thousands of cycles of transformation without wear.

Perhaps the most fascinating aspect is the integration of movement into the design narrative. The mechanics are not hidden away; they are celebrated. A rotating bezel on a transformable ring might be adorned with gemstones that align differently with each turn, creating new patterns of light and color. The act of transformation becomes a personal ritual, a tactile engagement between the wearer and the object. This transforms the jewelry from a static ornament into an interactive piece of art, deepening the emotional connection one has with it.

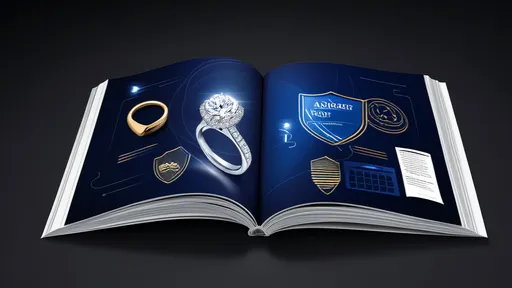

This engineering-driven approach also answers a growing desire for versatility and personalization in luxury goods. In a single purchase, a client acquires not one, but multiple pieces of jewelry. A complex necklace that becomes a tiara, a pair of earrings, and a brooch offers incredible value and adaptability. It allows the wearer to tailor their adornment to any occasion, mood, or outfit without the need for a vast collection. This practicality, born from complex mechanics, is a significant part of its allure.

However, the path from concept to finished piece is fraught with challenges. Prototyping these mechanisms is an exercise in patience and precision. Jewelers often work with 3D modeling and printing to test the kinematics of their designs before ever committing to precious materials. A hinge that works perfectly in a digital simulation might bind when rendered in metal due to friction or microscopic imperfections. Each iteration brings them closer to a flawless mechanism, but the process is painstaking and time-consuming.

Looking forward, the horizon of transformable jewelry is expanding into even more daring territory. We are beginning to see the incorporation of micro-springs, sliding tracks, and even elements inspired by origami and compliant mechanisms—where flexibility within the material itself creates movement without traditional hinges. The future points toward jewelry that doesn't just have two or three forms, but perhaps a dozen, all contained within a deceptively simple singular form.

In conclusion, the art of transformable jewelry represents a sublime fusion of aesthetic vision and mechanical ingenuity. It is a field where the jeweler’s torch meets the engineer’s caliper, creating objects that are as intellectually fascinating as they are beautiful. These pieces are testaments to human creativity, proving that even in the smallest of scales, we can build complexity, wonder, and endless possibility.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025