In the rarefied world of high jewelry, the creation of each piece represents a confluence of artistic vision and technical execution. For centuries, the craft relied exclusively on the skilled hands of artisans, with wax carving serving as the foundational stage where designs first took tangible form. The arrival of Computer Numerical Control (CNC) technology, however, introduced a paradigm shift, offering unprecedented precision and repeatability. This has not rendered the ancient art of hand-carving obsolete; rather, it has prompted a sophisticated and evolving partnership. The contemporary atelier is now a hybrid environment where the cold logic of the machine and the intuitive warmth of the human hand engage in a deliberate dance, each playing to its strengths to achieve a collective masterpiece that neither could realize alone.

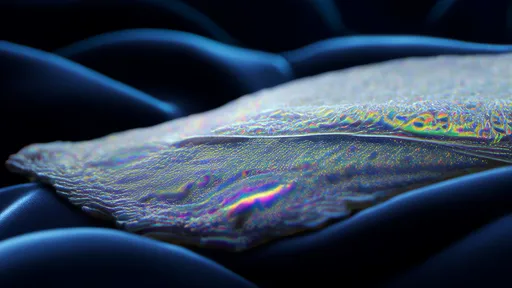

The artistry of hand-carving wax is a discipline steeped in tradition, requiring years, if not decades, to master. It begins not with code, but with a mental image and a block of wax. The carver, armed with an array of specialized tools, coaxes the form from the material through a process that is as much about feeling as it is about seeing. There is an intimate dialogue between the artisan and the medium—a slight change in pressure, the angle of a blade, the stroke of a file—each minute adjustment imbuing the model with a unique character. This manual process excels in capturing the organic, the fluid, and the emotionally resonant. The subtle asymmetry of a natural blossom, the soft undulations of a wave, or the nuanced expression of an animal's form are all territories where the human hand reigns supreme. It is in these details that the soul of a piece is often found, a testament to the artisan's touch that conveys a sense of life and movement impossible to code into a machine.

Conversely, CNC carving represents the pinnacle of digital fabrication, a process governed by mathematical certainty. A designer's concept is first rendered into a meticulous 3D model using specialized CAD software. This digital blueprint is then translated into a language of coordinates and commands that guide a precision milling machine. With robotic accuracy, a spinning cutter meticulously removes material from a wax block, replicating the digital model down to the micron. The advantages of this method are profound, particularly for designs that demand absolute geometric perfection. Complex architectural structures, intricate filigree patterns with repeating motifs, and settings that require flawless symmetry are executed with an ease and accuracy that would be immensely time-consuming and prone to human error by hand. Furthermore, CNC allows for perfect replication, enabling the creation of multiple identical components for a suite of jewelry or a limited collection with zero deviation between pieces.

The narrative within high jewelry is not one of replacement but of strategic integration. The most forward-thinking houses no longer see these methods as mutually exclusive but as complementary tools in a shared workshop. A common workflow begins with the digital realm. CNC is employed to establish the fundamental architecture of a piece—the primary form, the precise placement of stone settings, and the overall structural integrity are machined to perfection. This creates a flawless "canvas" or armature. This machined wax model then passes to the master wax-carver. Their role is to breathe life into the precise form. They might soften a sharp edge to mimic the wear of a sea-tumbled stone, add delicate texturing that resembles natural bark or skin, or sculpt flowing, naturalistic details that appear to grow organically from the core structure. This hybrid approach leverages the strength of each technique: the machine ensures structural perfection and precision, while the human hand injects warmth, narrative, and a unique artistic signature.

This fusion is perhaps most critical in the realm of customization and one-of-a-kind pieces, the haute joaillerie that defines the pinnacle of the craft. A client may bring a precious, irregularly shaped gemstone—a paraiba tourmaline with a unique watercolor hue or a rustic diamond crystal retained in its natural form. CNC technology can be used to scan the exact dimensions of the stone, creating a digital model that ensures its setting will be a perfect, secure fit. However, the design that grows around this central gem must celebrate its uniqueness. This is where the wax-carver takes over, sculpting elements that echo the stone's organic shape, perhaps weaving tendrils of wax around the digital scan model to create a setting that looks as if it was grown specifically for that one gem. The result is a piece that is technically impeccable yet feels entirely natural and bespoke.

Ultimately, the future of high jewelry fabrication lies in this harmonious synergy. The question is not whether machine or man is superior, but how best to deploy each to serve the ultimate goal: the realization of beauty and wonder. CNC carving provides the foundational excellence, the backbone of precision and complex engineering that supports ambitious designs. Hand-carving provides the narrative heart, the imperceptible imperfections and artistic flourishes that connect with the wearer on an emotional level. Together, they expand the very boundaries of what is possible, allowing designers to conceive pieces of breathtaking complexity and profound beauty. In the hands of a visionary creative director, this partnership ensures that the jewels of tomorrow will continue to carry the soul of a centuries-old craft, even as they are forged with the tools of the future.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025