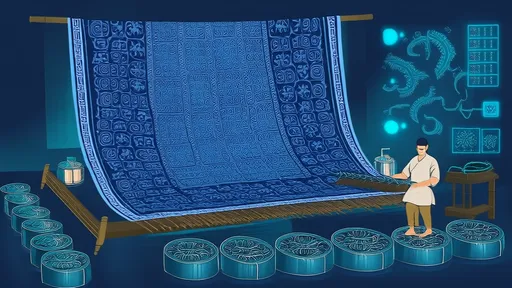

The textile industry has long been associated with significant water consumption and environmental impact, but a recent breakthrough in water-saving dyeing and finishing technologies promises to reshape the sector. A comprehensive industry white paper titled "Water-Saving Dyeing and Finishing: Pathways to Sustainable Textile Manufacturing" was unveiled this week, revealing groundbreaking innovations that could reduce water usage by up to 50% in certain processes. The report comes at a critical time as global fashion brands face mounting pressure to adopt eco-friendly practices.

Authored by a coalition of textile engineers, environmental scientists, and industry leaders, the white paper represents three years of collaborative research across twelve countries. What sets this study apart is its practical approach – rather than focusing solely on theoretical solutions, the document provides actionable methodologies that have already been successfully implemented in pilot programs. Several major apparel manufacturers contributed real-world data showing measurable reductions in water consumption without compromising fabric quality or color vibrancy.

The technologies highlighted in the report span the entire textile production chain. From pre-treatment processes that require less water to prepare fabrics for dyeing, to advanced dye application systems that maximize absorption rates, each innovation contributes to the overall water savings. Particularly noteworthy is the development of cationic modification technology, which alters fiber surfaces at the molecular level to dramatically improve dye uptake. Early adopters report achieving similar color depth with 30-40% less dye liquor, directly translating to reduced water needs for both dyeing and subsequent rinsing.

Perhaps the most surprising finding concerns the economic viability of these water-saving measures. Contrary to the perception that sustainability comes at a premium, the white paper demonstrates how many of these technologies actually lower production costs over time. Reduced water consumption means less energy needed for heating and wastewater treatment, while some of the newer dyeing techniques shorten processing times. One denim manufacturer cited in the report achieved a 17% reduction in total production costs after implementing a combination of these methods across their facilities.

The white paper doesn't shy away from addressing implementation challenges. While the technologies exist, widespread adoption requires significant retooling of existing infrastructure and retraining of workforce. The report includes detailed transition roadmaps for different types of manufacturing setups, from large-scale operations to smaller specialty dye houses. It also examines the policy landscape, identifying regions where government incentives are accelerating adoption and areas where regulatory barriers still hinder progress.

Industry response to the white paper has been overwhelmingly positive. Several global sustainability initiatives have already incorporated its findings into their certification criteria, and multiple textile machinery manufacturers announced plans to commercialize equipment based on the described technologies. As consumer demand for sustainable fashion continues to grow and water scarcity becomes an increasingly urgent global issue, this comprehensive report provides both the technical solutions and business case for transforming one of the world's most resource-intensive industries.

Looking ahead, the researchers emphasize that water-saving dyeing represents just one piece of the sustainability puzzle. The white paper concludes with a call for continued innovation across material science, renewable energy integration, and circular production models. With the textile industry accounting for approximately 20% of global wastewater, the potential impact of adopting these water-saving technologies could extend far beyond factory balance sheets, contributing meaningfully to worldwide conservation efforts and helping to future-proof the entire apparel sector.

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025